DIAMOND: The hardest material present on the earth. Like metal and rock, it is so powerful that it could penetrates almost all. Diamonds bred for performance can do many tough jobs. But diamonds, no matter how tough they are, may still wear out if we use them frequently and for a prolonged period of time. That means we must maintain diamond tools allowing them to live as long as possible.

Companies like Crysdiam have developed special coatings to prolong the life and strength of diamond tools. These coatings are thin layers applied to the tool diamond surface. They sort of protect the diamond from damage.

Coatings are quite significant because these coatings also prevent diamond tools from getting worn out too soon. Crysdiam adds various coats on diamond tools for more durability. Some of the coatings used are diamond-like carbon (DLC), titanium nitride (TiN), and titanium carbonitride (TiCN). And every coating type has its unique applications and benefits that improve the diamond tool performance.

There are plenty of solid reasons to utilize these lab produced diamond tools. A significant advantage of having a coating is that it minimizes friction. Friction is created when two surfaces rub together. Less friction means faster, but it all adds up to the tool lasting a lot longer. This maintains the diamond tool in a good condition for a longer period. This coating also acts as protection for the diamond from getting scratched or broken when we are using it. Also, coated diamond tools allow for faster cuts and more efficiency which is needed in a lot of jobs.

Crysdiam: Always Seeking New Concepts and Innovations for Their Diamond Tools. They have developed one new innovation called a multi-layer coating. This means a blade is electrically charge build with more than one layer of coating into the tool, and improves strength and enhance wear-resistance. They also developed a special type of coating, known as "nano-diamond such as diamond coatings. this coating is literally microscopic, the diamond particles are one-thousandth the size of a human hair! The special coating can further strengthen the diamond tool.

Choosing the appropriate coating for your diamond tool starts with a consideration of how you will use the tool. This is because not all coatings perform better on every surface. Certain coatings are after all better for cutting through metal, for instance, while others are best on stone or glass. At Crysdiam, there are professionals who can guide you on the right coating depending on your requirements and from what tool to use.

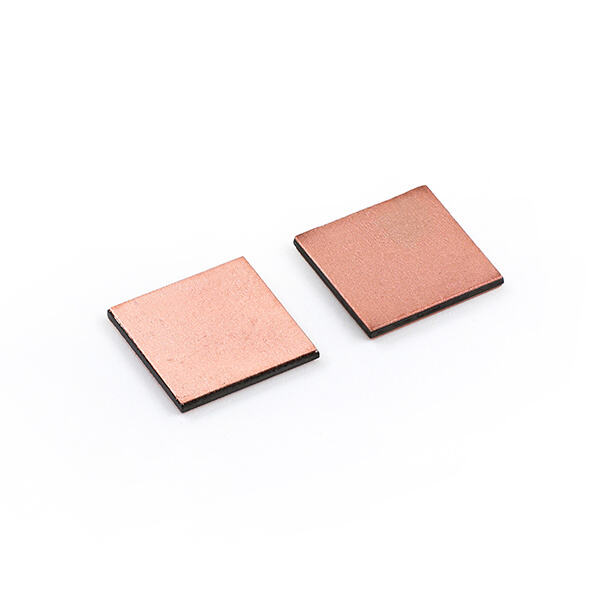

coated diamond is one of the very few CVD producers around the world capable of producing lab-grown colored diamonds with colors like D/E/F, are now advanced. Our development technologies for fancy colored lab-grown stones like pink and blue have also been improved. Crysdiam can also provide high-quality lab-grown stones in calibrated sizes. This will increase the efficiency of jewelry manufacturing processes.

Our single-crystal CVD has a maximum of 60mm x60mm We can dope diamonds with elements like N and P to achieve the coated diamond of 1ppb We also have the high-precision process capability to produce diamond surface roughness lower than 0 5nm Crysdiam's diamond-based advanced material can be used in research and industrial applications

In 2013, Crysdiam took the lead in developing MPCVD reactor with complete intellectual property rights in China. Crysdiam has also developed its own coated diamond and grinding, polishing and polishing equipment. Crysdiam can quickly respond to customer needs and provide customized products by vertically integrating RD in equipment, diamond manufacturing, the processing of diamonds and jewelry manufacturing.

coated diamond more than 1500 MPCVD reactors and a fully equipped, state-of-the art factory, Crysdiam ranks as a the top manufacturer in terms of production scale and technological level. Our stable supply of lab-grown diamonds in a variety of shapes, sizes and colors will address the worries our clients have concerning supply chain security.

White and fancy color lab-grown diamonds in various sizes and shapes;

Offered as certified/uncertified stones, matched pairs, and calibrated parcels.