Do you know anything about single crystalline diamond? A single crystal construction makes this type of diamond unique to the rest of the gemstones, which are many small crystals formed together. Single crystal diamonds are super special because they have these incredible properties that make them really unique and valuable, and a lot of different industries use them for different reasons. A company that produces this rare and expensive type diamond is named Crysdiam. So they are dedicated to producing the highest quality single crystal diamonds.

In fact, one of the most amazing aspects of single crystal diamond is its incredible strength. As a matter of fact, it is considered to be the most efficient natural material found on the Earth! 600 Degree Celsius, which means it is heat and pressure absorbers material. So if you started putting tons of weight on it or heating it to super high heat, it wouldn’t fall apart. This strength makes single crystal diamond ideal for manufacturing cutting tools and other long-lasting products.

Single crystal diamond, how far it has come in the many industries that this material has impacted! In manufacturing, for example, it has completely transformed the production of cutting tools. Due to its incredible strength, single crystal diamond tools can easily cut through some of the hardest materials. This allows factories to operate at higher speeds and increase efficiency in production, which is a tremendous advantage for companies aiming to reduce time and costs.

Single crystal diamond is also an important segment in the medical field. It is ideal for creating surgical instruments such as scalpels and drills, as it is able to withstand very high temperatures and pressures. Surgeries are performed faster and with better precision, resulting in better outcomes and recovery times for patients. It allows doctors to do delicate and crucial operations knowing they are using the best materials possible.

The advent of single crystal diamond has revolutionised the manufacturing sector. It is so strong that it can snap through a few of the hardest materials with ease. What this translates to is that manufacturing processes can be carried out significantly faster and more efficiently, which directly results in enormous cost savings for companies. Businesses can produce products quicker helped service and customer care, which enhances their overall success.

Furthermore, its resistance to extreme temperatures and pressures makes single crystal diamond suitable for high-pressure and high-temperature applications. This has resulted in greater adoption of single crystal diamond in the oil & gas sector. It is used in drilling and exploration in oil & gas sector. Moving forward, the advantages of being able to work with such a powerful material in more difficult environments have changed the way companies have operated in this area.

Crysdiam's diamonds are made through a process called chemical vapor deposition. The procedure utilizes a composite of gases that are surely heated to extreme temperatures. The gases warm, and the diamond builds up in layers. It takes significant accuracy and attention to detail to ensure the diamond is growing the right way and at the rate you need it to. It is this attention to detail that enables Crysdiam to manufacture superior quality diamonds.

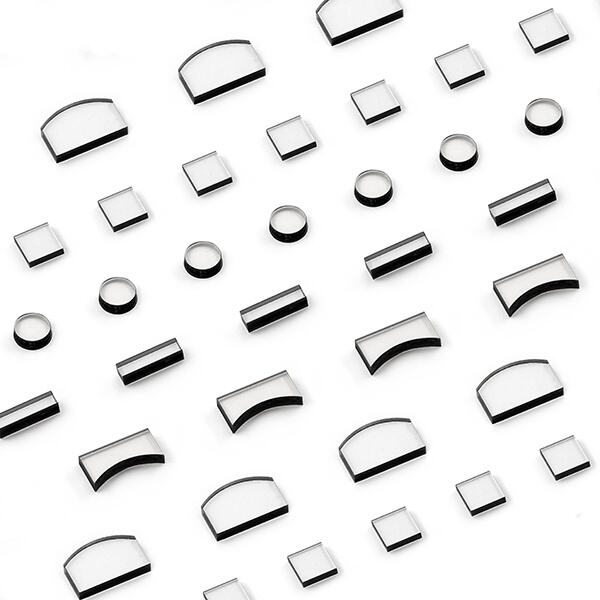

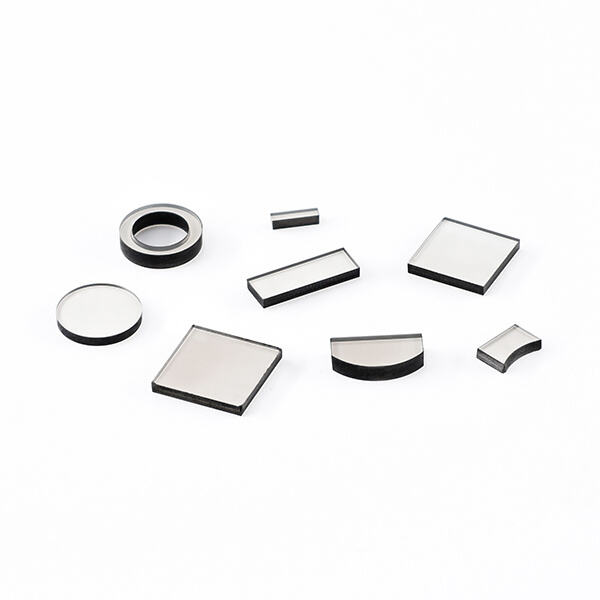

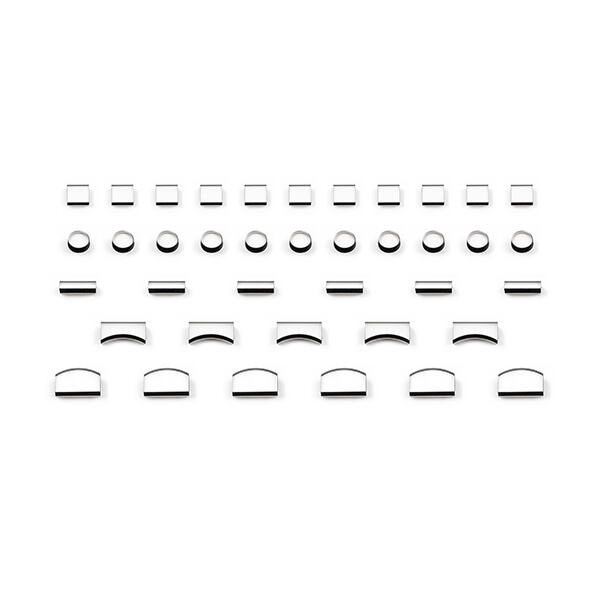

Crysdiam is a leader in the manufacturing of single crystal diamond grown in labs, having over 1500 MPCVD Reactors and an ultra-modern facility. Our steady inventory of lab-grown diamonds in a variety of shapes, sizes and colors will alleviate the concerns of our customers about supply chain security.

Crysdiam is single crystal diamond the few CVD makers in the world capable of producing lab-grown colored diamonds with colors like D/E/F, are now well-established. Our technology for growth of fancy colored lab-grown stones, such as blue and pink have been improved. Additionally, Crysdiam is able to provide top quality lab-grown diamonds in calibrated sizes, which can significantly enhance the efficiency of subsequent jewelry manufacturing processes.

The current maximum size of our single crystal CVD diamond is 60mm and 60mm We can carry out quantitative doping with elements like P and N producing a high-purity diamonds of 1ppb Our single crystal diamond capability allows us to achieve diamond surface roughness less than 0 5nm The advanced diamond materials produced by Crysdiam will meet the requirements of industrial research and scientific applications

Crysdiam was the first company to build an MPCVD reactor in China in 2013. Crysdiam has full single crystal diamond. Furthermore, Crysdiam independently developed various types of laser equipment as well as grinding and polishing equipment. Crysdiam is able to rapidly react and create custom products by vertically linking RD in equipment, diamond production, processing diamonds, and jewelry manufacturing.

White and fancy color lab-grown diamonds in various sizes and shapes;

Offered as certified/uncertified stones, matched pairs, and calibrated parcels.