Do you know what a lab diamond is? That sounds like a candy you could eat, well, not at all, because it's something else! Diamond Wafers: An ultra-thin slice of Diamond used in tech Diamond wafers are primarily found in critical electronic products, such as mobile telephones, computers, and related devices employed daily. The reason diamond wafers are special is because of their significant strength and they can outlast normal wafers which are created from alternative materials.

Their Current Importance Semiconductors are extremely crucial components in electronics. They help run all the gadgets we use, including our tablets, game consoles and smartphones. So, without semiconductors, these devices are not functional at all! Diamond wafers are the future of semiconductors as they are significantly more powerful and are capable of withstanding higher temperatures when compared to typically used wafers. This is extremely useful since it allows them to be implemented into electronics that need to run really well, especially in conditions where it can become hot.

Microelectronics are small components used in many crucial products, including medical devices that aid doctors and sensors that respond to our surroundings. Diamond wafers have proven advantageous for these small devices due to their robust lifetime. They are also able to cope well at high temperatures. This is really important because tiny devices, such as ones present in phones and medical instruments, can get very hot while they are in use. Diamond wafers play a key role in ensuring that these devices remain functional without overheating.

Diamond wafers were a new product that was transforming the electronics industry. The process called electronic manufacturing. Diamond wafers allow for devices to be more durable as well as have higher performance than previous generations of semiconductors. That means we’ll benefit from the electronics we all use every day performing better, and for much longer. It means you can even play with your phone without much thought put into breaking something or needing the phone replaced every now and then!

The small parts that go into every electronic device we own. These parts are getting even better than they already were, thanks to lab produced diamonds. They are robust and can withstand additional stressors, which means they are less likely to snap. They are also suitable to be used at high temperatures making them suitable for powerful and efficient electronic devices. This is great that companies can develop new devices to do more things without overheating or going down.

Stealth high-quality diamond wafers producer Crysdiam. We offer improved diamond wafers because our diamond wafers are stronger than your average diamond wafers. We feel diamond wafers are the new paradigm in building electronic devices, and we are committed to delivering the best diamond wafers in the industry. We want to create it, leading to working better and lasting longer electronics to makes electronics for all of the technology.

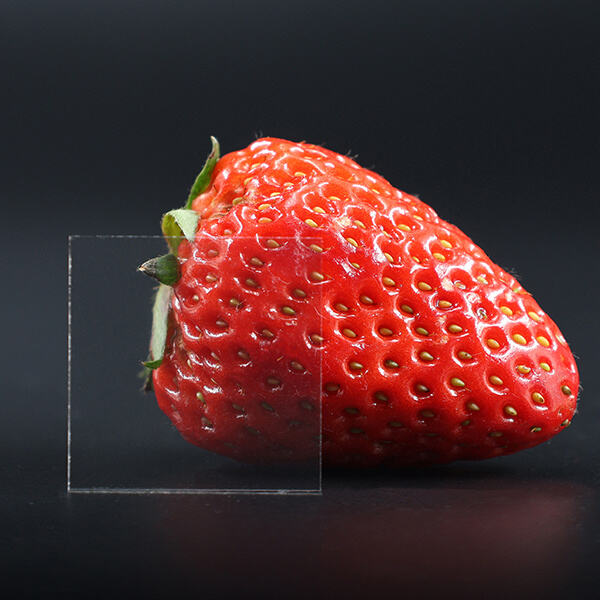

diamond wafer is one of the very few CVD producers around the world capable of producing lab-grown colored diamonds with colors like D/E/F, are now advanced. Our development technologies for fancy colored lab-grown stones like pink and blue have also been improved. Crysdiam can also provide high-quality lab-grown stones in calibrated sizes. This will increase the efficiency of jewelry manufacturing processes.

The current maximum size of our single crystal CVD diamond is 60mm and 60mm We can carry out quantitative doping with elements like P and N producing a high-purity diamonds of 1ppb Our diamond wafer capability allows us to achieve diamond surface roughness less than 0 5nm The advanced diamond materials produced by Crysdiam will meet the requirements of industrial research and scientific applications

Crysdiam was the first company to build an MPCVD reactor in China in 2013. Crysdiam has full diamond wafer. Furthermore, Crysdiam independently developed various types of laser equipment as well as grinding and polishing equipment. Crysdiam is able to rapidly react and create custom products by vertically linking RD in equipment, diamond production, processing diamonds, and jewelry manufacturing.

Crysdiam is a pioneer in the production of diamond wafer diamonds, with over 1500 MPCVD Reactors, and an ultra-modern manufacturing facility. Our steady inventory of lab-grown diamonds of various shapes, sizes and colors can address the concerns that our clients have about supply chain security.

White and fancy color lab-grown diamonds in various sizes and shapes;

Offered as certified/uncertified stones, matched pairs, and calibrated parcels.