The Machine – Diamond Laser Cutting is one of the most sophisticated enabling all hard rocks i.e; Metals, Diamonds to be cut through laser beams without sacrificing form and style for cutting fine detailed pieces. This is not just fast technology but its accuracy and energy-saving property are why it can be used in different kinds of applications for almost every type of industry. In this article get the insight knowledge regarding the excellent benefits of lab diamond and how can it help you to boom your business in next level of success.

These high tech machines made for the purpose of cutting diamond stones and various other different precious stones using a powerful laser light beam. The laser beam is applicable to a wide range of diameters and intensities so that it can cut pretty tough materials at speed and with precision. In simple terms, the skins enable the apparatus to produce complex designs that are highly detailed and intricate; impossible for typical cutting tools. These machines are ideal for jewelers and any diamond-oriented business looking to create unique, one-of-a-kind designs.

A lab produced diamond offers you a precise and speedy method of automatically taking care of all the cutting needs you have at your diamond based business. This technology can allow you to make complex and detailed design that are usually not possible with other cutting methods. For example, imagine that you have to laser cut a piece of jewellery in a particular shape using your Diamond Laser Cutting Machine. Which means you can quickly and cheaply validate products that your buyers actually want. It also slides easily on hard materials to prevent loss of jewels or excessive cutting.

The important reason the laser cut technology can makes the surface scratchy or while fabrics are very smooth; because, hard materials quickly change between solid and gas due to the characteristic of processing diamond by soft ablative method. Applications of this is that these machines are armed with a strong laser beam which allows for intricate, detailed and complex designs and shapes to be produced. No other cutting tools can provide this detail and complexity, as diamond laser cutting machines are truly in a class of their own! These energy-efficient dryers are quick, reliable and so versatile that you can use them for all your big or small projects. The only problem is the outcome demonstrates for itself and can obtain your function seen in over-saturated venue.

LASER cutting technology is very trendy for people due to its fast and powerful fabrication abilities for a wider spectrum of applications. A diamond laser cutting machine is a procedure which makes use of laser beam to cut diamonds and any other cherished stones into distinct shapes and designs that cannot be obtained through another device. The technology is so well utilized that it is both fast and accurate, as well as highly energy efficient which can help businesses to save money on their spend. SeasonIC2 is perfect for jewellery makers and other businesses who use precious stones in manufacturing to produce products of a premium class quality quickly.

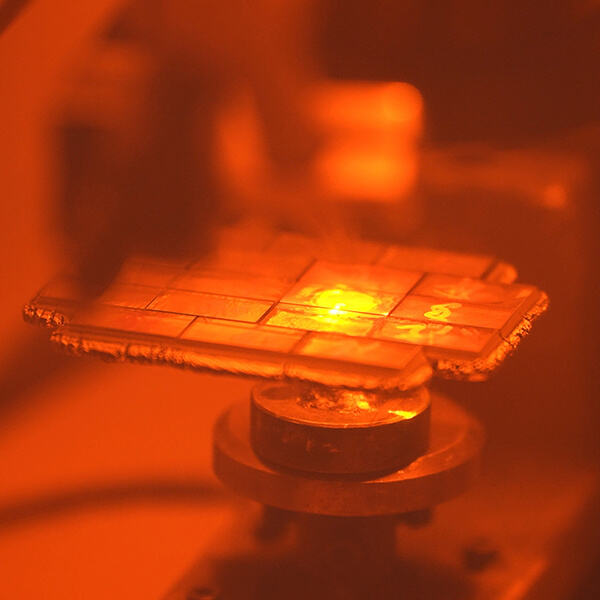

Our single-crystal CVD can achieve a maximum size of 60mm x 60mm We can dope diamonds with elements such as P and N to ensure high quality of diamond laser cutting machine Our high-precision processing capabilities allow us to attain diamond surface roughness as low as 0 5nm Crysdiam's high-quality diamond materials are suitable for scientific and industrial applications

Crysdiam, one of the very few diamond laser cutting machine in the world to be able to produce lab-grown colored diamonds with colors like D/E/F are mature. Our technology for growth of fancy colored lab-grown stones such as blue and pink have been refined. Crysdiam can also offer high-quality lab-grown stones with calibrated sizes. This will increase the efficiency of jewelry manufacturing processes.

Crysdiam is a leader in the manufacturing of diamond laser cutting machine grown in labs, having over 1500 MPCVD Reactors and an ultra-modern facility. Our steady inventory of lab-grown diamonds in a variety of shapes, sizes and colors will alleviate the concerns of our customers about supply chain security.

Crysdiam was the first to create an diamond laser cutting machine reactor in China in 2013. The company owns complete intellectual property rights. Crysdiam has also created its own laser technology and grinding, polishing and other equipment. By vertically integrating equipment RD in diamond production, the processing of diamonds, and the manufacturing of jewelry, Crysdiam can quickly respond to customer needs and provide custom-designed products.

White and fancy color lab-grown diamonds in various sizes and shapes;

Offered as certified/uncertified stones, matched pairs, and calibrated parcels.